Injection Valves

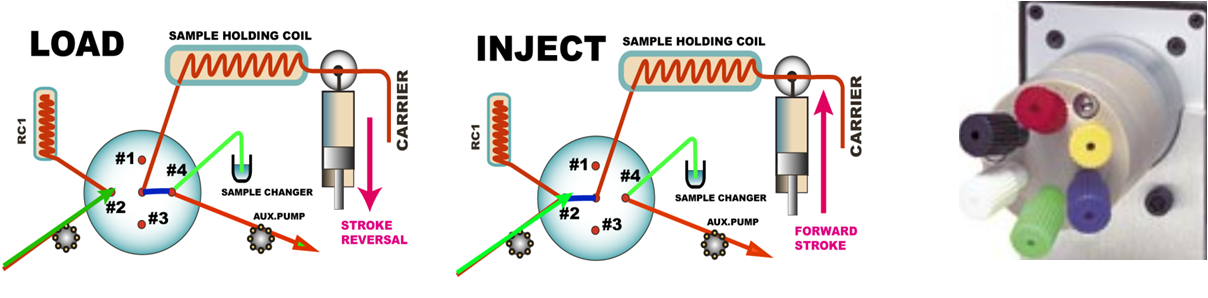

A two position, six port injection valve with a fixed loop is the most frequently used tool for injection of well-defined sample volumes. The volume of the external loop (shown above) is selected between 20 and 100mL by changing the length and I.D of the loop tubing. The valve can be switched from load to inject mode manually or automatically, and the loop can be filled either manually by syringe, or automatically from an autosampler by means of a pump. It is important to keep the length of the conduit between sample container and port #4 as short as possible, in order to save sample material, and to avoid sample-to-sample cross contamination. Introducing an air bubble and wash between samples is useful, but requires exact timing so that the injected volume is air free and contains undiluted sample.

1.4.6.

A six port multiposition valve combined with a syringe pump is the key component of all Sequential Injection systems (See Chapter 2). It allows injected volumes to be chosen at will, and at a selected flow rate.